757 N 12th St. Salina, KS 67401 (785) 342-7100

Email Us www.jimsmotorsports.com

757 N 12th St.

Salina, KS 67401 (785) 342-7100

Email Us

www.jimsmotorsports.com

Local / Inexpensive Service & Repair Visit Our Climate Controlled Showroom.

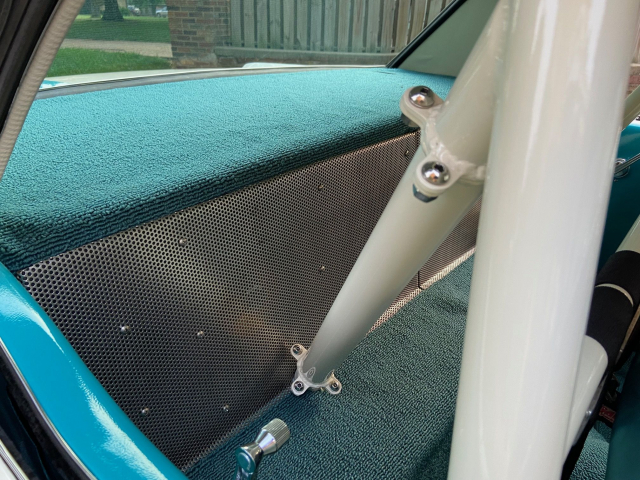

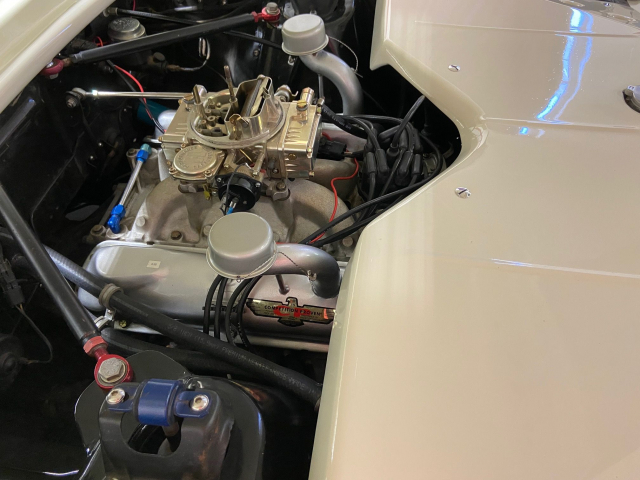

1966 FORD MUSTANG PRO TOURING WALK AROUND VIDEO AVAILABLE UPON REQUEST IT WOULD BE DIFFICULT TO EXAGGERATE THE AMOUNT OF FABRICATION THAT WENT INTO THE CONSTRUCTION OF THIS UNIQUE AUTOMOBILE. IT TOOK MANY YEARS TO BUILD BY A PROFESSIONAL SHOP. THE WOMAN CO-OWNER OF A WELL KNOWN ROD SHOP WAS RESPONSIBLE FOR ALL OF THE THE FABRICATION AND THE BUILD. THE CAR WAS PURCHASED NEW BY HER MOTHER! THE FOLLOWING IS A NOT SO BRIEF DESCRIPTION. * THE CAR BEGAN ITS LIFE AS A 1966 MUSTANG COUPE. * A TEXAS CAR 292 C.I. which was built to Holman-Moody specifications 12.5 Compression Ratio 330 HP @ 7200 RPM Solid lifter cam; valve lash is 0.22 hot 1. Modifications in the Engine Compartment a) Fabrication Related • Custom Panel to Divert Air in Front of Radiator • Custom Panel to Divert Hot Air Under Air Filter • Custom Upper Radiator Support • Custom 1 1/4†Rolled Tubing Welded onto Firewall Seam • Custom Export Braces with 1/2†Hiem Joints • Custom Curved Monte Carlo Brace Constructed from 1 1/4†Tubing • Custom Hood Latch/Oil Cooler Bracket Constructed b) Air/Fuel Related • Aluminum Intake • 390 cfm Holley Carburetor • Stainless Steel Throttle Linkage with 5/16†Hiem Joints • Chrome Air Cleaner • Remote Four Inch Fuel Filter Canister c) Electrical Related • One-Wire Alternator • Alternator Isolator • 60 Amp Marine Grade Circuit Breaker • Taylor Stainless Core Plug Wires • Custom Wiring in Engine Compartment d) Oil System Related • Holman Moody Stroppe Valve Covers • Dual Crankcase Breathers • Aluminum Oil Pan • Remote Oil Cooler Mount Adapter • Engine Oil Cooler • Stainless Steel Braided Oil Lines e) Cooling Related • Four Core Aluminum Radiator • Sure Grip Stainless Steel Hose Clamps • Heater Core Added f) Miscellaneous Modifications • Hood Finished Out Underneath • Assembled using Stainless Steel Button Head Bolts • Stainless Steel Hood Latch Pin 2. Interior Modifications a) Fabrication Related • Dash Pad and Bracket Removed • Custom Dash Panel Constructed From LH Corner of Dash to Glove Box • Individual Gauge Pods Constructed with “Eye Brows†• Custom Roll Bar Constructed Slightly Modified from Original Design • Roll Bar Bolted directly to Sub Frame Rather than Floor Pan • Rear Package Tray Extended Forward Eight Inches • Custom Speaker Cover, Console Top, and Glove Box Panel Constructed using Stainless Steel Perforated Material b) Parts Installed • Auto Meter Traditional Gauges Utilized • Three Inch Seat Belts • Three Inch Shoulder Belts • Fire Extinguisher • Wood Rim Steering Wheel c) Audio System • Clarion Remote Head Unit • Two Polk Audio Amplifiers • Two 8†Polk Sub Woofers • Four 6†Polk Mid-Range Speakers • Four 3 1/2†Polk Speakers • Two Polk Tweeters 3. Body Modifications a) Fabrication Related • Custom Perforated Stainless-Steel Grill • Drip Rails Removed • Cowl Vent Removed and Replaced with Custom Louvered Panel • Custom Lower Fender Lip Constructed to Replace Single Bolt Attachment to Body with a Three Bolt Attachment (Allows Better Adjustment) • Passenger Side Door Lock Removed • Trunk Lock Removed • Gas Cap Removed • Rear Valance Hemmed and Louvers Added b) Parts Installed • Fiberglass Hood with Shelby Scoop • Shelby Front Lower Valance • Oil Cooler Installed in Lower Valance • Shelby Rear Side Scoops Molded into Quarter Panels • Outside Mirrors Installed • Wheel Smith Rear Wheels- 15†x 7â€, 3.75†Back Spacing • Wheel Smith Front Wheels- 14†x 6â€, 3.5†Back Spacing • Rear Tires 225/70 R15 • Front Tires 195/75 R14 c) Paint • Custom Two Tone Paint Scheme with Inverted Lemans Stripes • Ford Wimbledon White and Custom Matrix (brand) Turquoise base coat • Matrix Euro Clear Coat 4. Trunk Modifications a) Fabrication Related • Custom Brackets Fabricated for Jack, Jack Handle, and Spare Tire • Custom Box/Mount Constructed for Battery Disconnect Switch • Custom Battery Box Tray • Custom Bumper Bracket Mount Fabricated and Connected to Front Roll Bar using 1 1/4†Tubing • Moved Fuel Fill Neck From Center to Passenger Side • Custom Stainless Steel Fuel Tank Vent Line • Custom Trunk Release Designed Utilizing Morse Cable System • Custom Metal Firewall Constructed Using 20 Gauge Sheet Metal b) Parts Installed • Battery Disconnect Switch with Custom Battery Cables • Battery Box • Stainless Steel Fuel “Catch Bowl†• Competition Jack • 36 Gallon Fuel Cell Replaced with 22 Gallon Fuel Tank c) Miscellaneous Trunk Modifications • Raptor (brand) Tintable Bed Coating Sprayed Throughout Trunk • Underneath of Trunk Finished Out • Trunk Components Assembled using Stainless Steel Button Head Bolts 5. Modification Underneath Car a) Fabrication Related • Custom Sub Frame Connectors Constructed from 1 ¾†Tubing • Sub Frame Connectors Connected to Rocker Pinch Weld Utilizing 1 1/4†Tubing and Welded Front to Back • Traction Masters Mount to Outside of Sub Frame Connectors • Custom “X†brace built to connect front frame rails to rear subframe connectors b) Parts Installed • Flowmaster 2 1/2†exhaust system from Front to Rear • 1966 Galaxy Wagon Rear Brakes • 1966 Galaxy Wagon Front Brakes • Four Leaf 120lb Rear Springs • 620lb Front Springs • 1†Front Sway Bar c) Drivetrain Related • 2.60:1 Rear End Gear Ratio • T-5 Borg Warner manual transmission d) Miscellaneous Modifications Under Car • Underneath of Car Coated with Raptor Bed Coating THE CAR RUNS AND DRIVES GREAT (NO RATTLES) APPROXIMATELY 530 MILES ON THE BUILD IF YOU CONSIDER THE HUNDREDS OF HOURS OF WORK COUPLED WITH FIRST CLASS MECHANICAL COMPONENTS, THIS BUILD WOULD EASILY EXCEED $100,000.00 REALISTICALLY PRICED TRADES UP OR DOWN WILL BE CONSIDERED (THAT MEANS DON'T VALUE YOUR $20,000 TRADE AT $50,000!) |

|

|

|

|

|

|

|

|

|

]]]]]]]] |

|

|

|

|

|

|

|

|

|